BRISKHEAT LYNX TEMPERATURE CONTROL SYSTEM

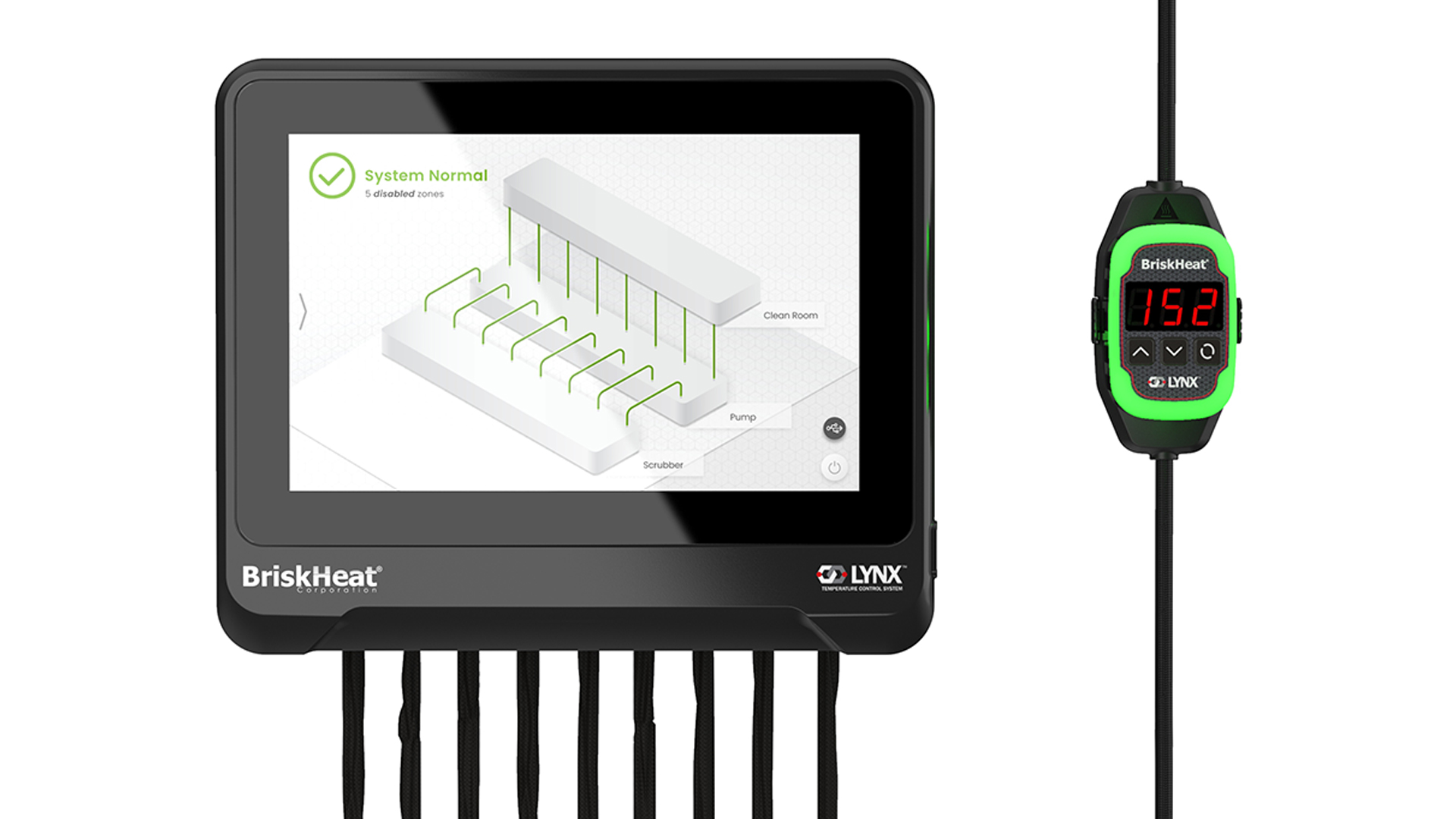

BriskHeat’s new LYNX™ temperature control system includes a network of heating jackets and temperature control modules connected to a central operator interface which allows the system to be monitored and controlled from one location.

To bring this system to life, a complete product development design effort included user experience, industrial design, electrical engineering, and software engineering teams as well as close collaboration with BriskHeat’s internal engineering project leads and engineers. This cross-functional effort led to a state-of-the-art system that allows for over 1,000 zones to be centrally controlled in one-easy-to-use system.

ClientBrisk HeatServicesUX/UI Design, Usability Research, Industrial DesignYear2019

BACKGROUND & GOALS

BriskHeat’s temperature control system for semiconductor fabrication facilities, started as a 12-year-old design that needed help moving into the next generation. The re-design consisted of two products within the system:

- A temperature control module that interfaces to BriskHeat’s heating jacket solutions that required industrial design, mechanical engineering and visual brand language

- The operator interface which included industrial design, user experience design, mechanical engineering, electrical engineering and software engineering.

BriskHeat had a few main goals for the new hardware:

- Achieve a small footprint for the control module without sacrificing high performance.

- Improve the visibility of the individual modules via a large LED array to indicate temperature or information codes.

BriskHeat had straightforward goals for the UX/UI:

- Improve the interaction and setup for the user allowing for flexibility in the user’s installation.

- Inspect, troubleshoot, locate, and push updates to each module.

OPERATOR INTERFACE UX/UI

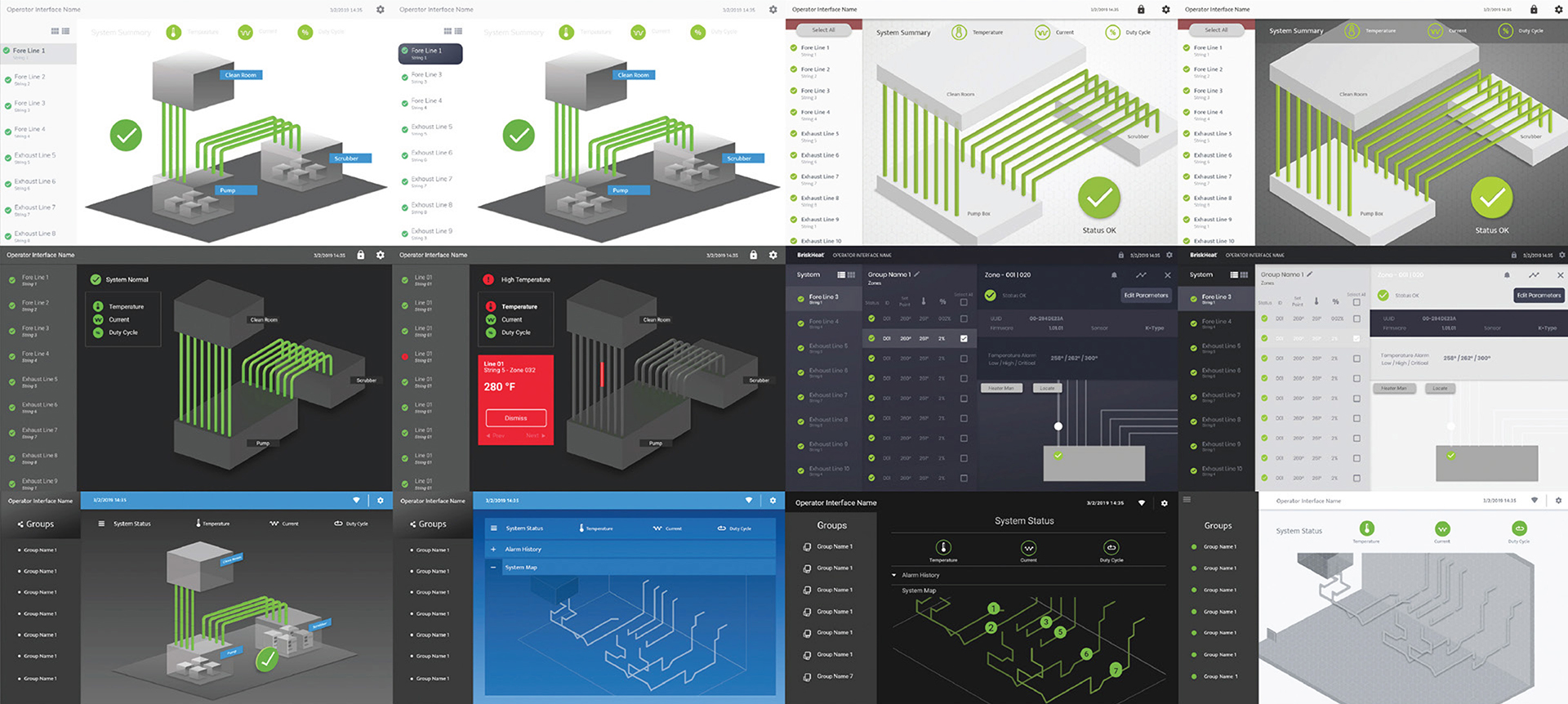

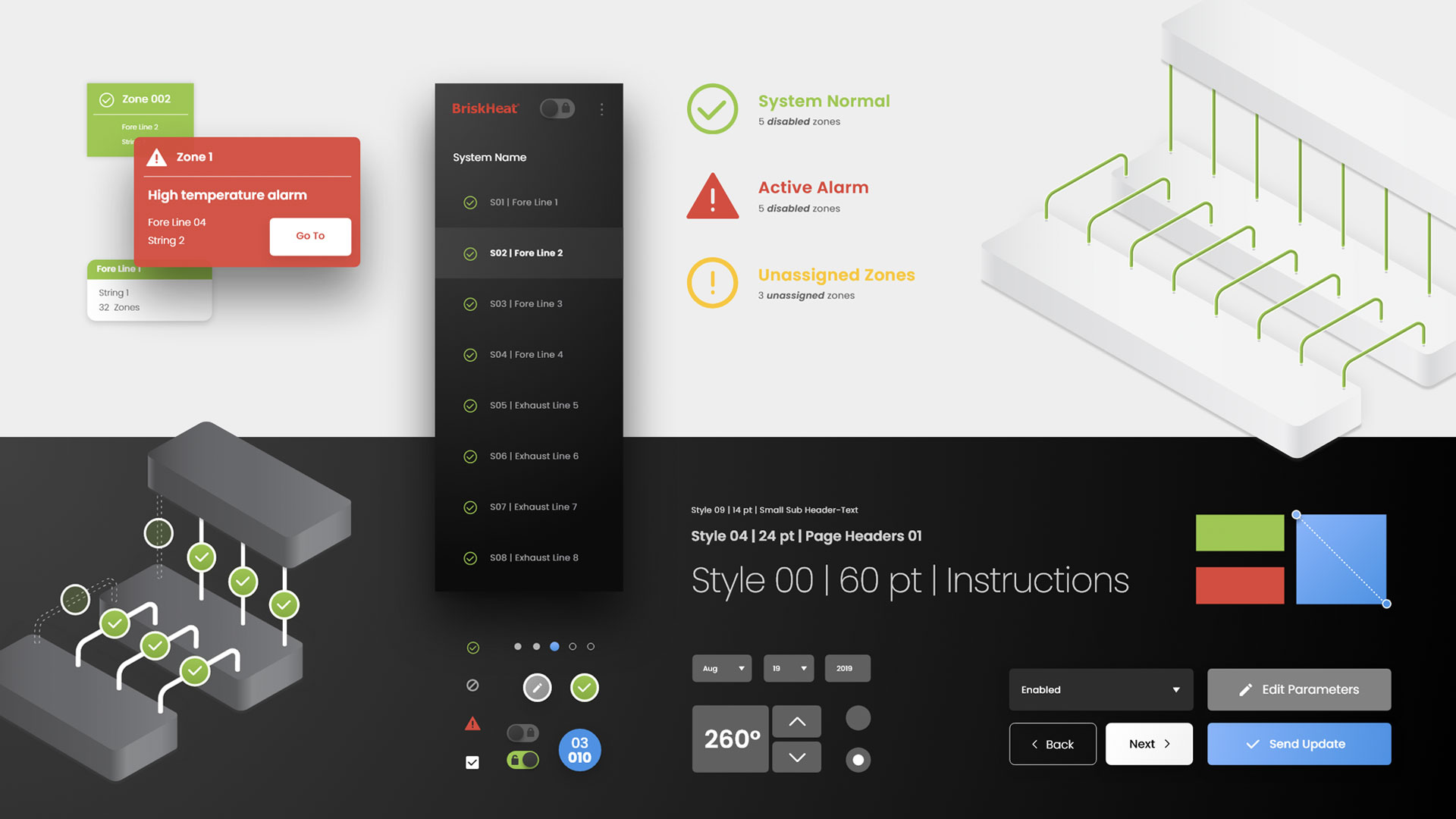

For the operator interface, the redesign focused on creating a simple first time setup procedure, ability to visually layout the user’s installation and associate zones, and to easily monitor and control the system and zones. Another target was to provide a way for the user to manage zones for maintenance and quality control by allowing easy reconfiguration and review of historical data. The user experience design team started with understanding the requirements and the users of the existing operator interface and temperature control module system. After reviewing the existing product and gathering information from BriskHeat about the user, we identified two primary users:

- The Tool Owner who is responsible for keeping the facility up and running.

- The Technician who is primarily responsible for installation and troubleshooting issues in the field.

With information from BriskHeat, there was had an understanding of the users, context, and content. We set out on developing the information architecture by creating a system map to bring together the feature requirements and user needs into one system. Once reviewed, we developed wireframe concepts that focused on flow and structure of the user interface and tested this against the user tasks generated from the user needs.

UI REFINEMENTS

After reviewing wireframes with BriskHeat, we implemented the feedback and developed the style and brand language for the user interface by creating aesthetic user interface concepts that were layered on various wireframe concepts. After an internal heuristics review, we met with BriskHeat to narrow down the selection of aesthetic concepts into one refined direction in alignment with BriskHeat’s existing brand language. From this, we developed the user experience documentation that the software engineering team utilized to fully implement the system, along with the functional specification.

A UNIFIED SOLUTION: HARDWARE + SOFTWARE

Together, the final system of temperature control modules with an operator interface creates an improved system, allowing the user to quickly monitor and control a whole facility. The system design provides the user with the ability to quickly identify alarms to mitigate any issues and maintain production output. Users can see indicator lights on each module with a 360-degree light ring. The 10.1” touchscreen lets the tool owner customize maps of zones within the facility, and update up to 1024 zones at one central location.